News

Honest and trustworthy, enterprising

On February 21, Gwangju Advanced Institute of Science and Technology (GIST, President Kichul Lim) announced that the research team of Prof. Dong-Seon Lee from the School's School of Electrical Engineering and Computer Science has developed a long-range homoepitaxy technology for gallium nitride (GaN) semiconductors using only metal-organic chemical vapor deposition (MOCVD).

Epitaxy technology, which is the growth of semiconductor materials into well-aligned films in semiconductor manufacturing, is crucial for semiconductor manufacturing. GaN remote homogeneous epitaxy using epitaxy technology forms two-dimensional materials on GaN chips. GaN semiconductors of the same quality as the chip can be grown on the chip and easily removed, enabling the continuous production of GaN semiconductors using a single GaN chip.

Thanks to its high-speed switching, low loss and high efficiency characteristics, GaN semiconductors have attracted much attention as power semiconductor materials for next-generation electric vehicles, and are expected to be widely used in industry.

But due to technical limitations, traditional epitaxy requires chips about 1,000 times thicker than 1 millimeter to achieve the actual semiconductor material effect of about 1 micron thickness.

Therefore, in 2017, the research team of Professor Jihwan Kim at MIT proposed a "remote epitaxy" technique that overcomes existing difficulties by using molecular beam epitaxy methods, which attracted a lot of attention.

The "remote epitaxy" technique proposed by Professor Jihwan Kim's team is a unique method for forming a very thin two-dimensional material similar to graphene on a chip and growing a semiconductor material on top of it.

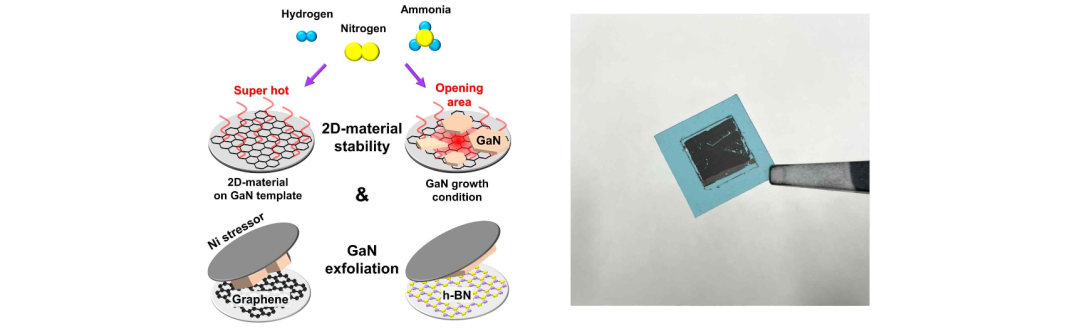

▲ Experimental diagram and sample image of stripping by nickel stress device. Before GaN growth, the stability of the two-dimensional material formed on the chip was tested, and then GaN growth was performed. Nickel is deposited on the surface of the growing GaN and stripped using heat release tape.

The technology not only makes it possible to obtain high-quality semiconductor material that "replicates" the chip's properties in thin film form, but also "strips" it off the chip, theoretically making it infinitely reusable.

The technology takes advantage of the electrical properties of the chip's surface to penetrate graphene membranes. Since the semiconductor material is not directly bonded to the chip through a two-dimensional material, only the semiconductor material can be stripped.

In particular, GaN semiconductors, which are widely used in LED displays and electric vehicle charging devices, require GaN chips to achieve maximum efficiency, but sapphire chips with crystal quality of only 1/1000 level have been used since their price is about 100 times that of sapphire chips. Therefore, the remote epitaxy technology that can reuse expensive GaN chips has received great attention.

Until now, GaN long-range epitaxy techniques have been known to be possible only through the simultaneous use of molecular beam epitaxy and metal-organic chemical vapor deposition methods. This is because when only the "metal-organic chemical vapor deposition method" is applied to the remote homogeneous epitaxy technology, the GaN chip surface decomposes under high temperature growth conditions, and the two-dimensional material insertion layer is damaged.

To solve this problem, Professor Dong-Seon Lee's team only used the "metal-organic chemical vapor deposition" method, which is widely used in industry. By growing a low-temperature GaN buffer layer on a GaN chip to form a two-dimensional material on it, GaN long-range homoepitaxy technology that can completely cover and protect two-dimensional materials has been realized for the first time, thus growing and stripping GaN semiconductors.

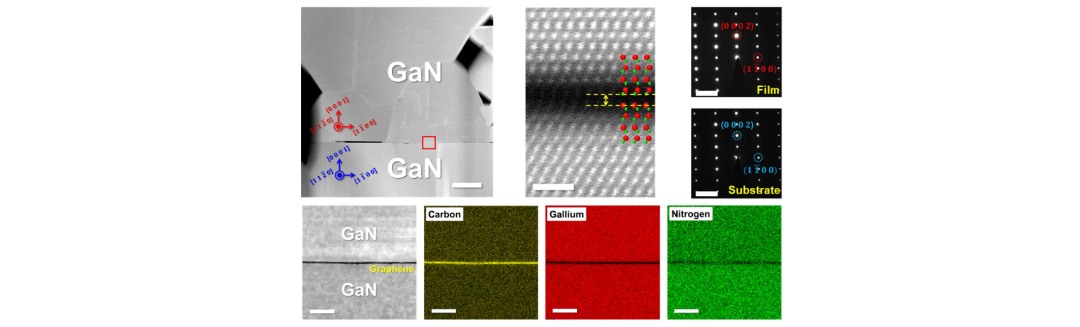

▲ Precise analysis to confirm long-range homogeneous epitaxy. Using transmission electron microscopy, they confirmed the epitaxial relationship between the GaN chip, the graphene and the grown GaN at the atomic scale, and verified that the graphene remained after growth.

Professor Dong-Seon Lee said: "This study enables the 'GaN remote homoepitaxy' technique, which was previously considered impossible. Although it is still in its early stages, we hope to lead the future market for microleds and next-generation GaN power semiconductors based on this technology, and apply it to future displays."

The research, led by Professor Dong-Seon Lee and conducted by PhD student Hoe-Min Kwak, was supported by Professor Sang Ho Oh's research team at the Korea Institute of Energy Technology, As well as the nanomaterials Technology Development Project and individual research project (Intermediate research) of the Korea National Research Foundation under the Ministry of Science and Information and Communication Technology, Published online on December 12, 2023 in ACS Applied Materials & Interfaces, a leading international journal in materials science and chemistry.